The Complex Relationship and Looming Crisis Between Our Thirst For Water and Our Hunger for Energy

October 19th, 2016

Via China Water Risk, a look at how unconventional water sources can help power China:

Thermal power plants are intensive water users and a lot of China’s thermal power generation capacity is located in highly water stressed regions. In these regions, the power sector can be a significant contributor to water stress. In a bid to protect precious freshwater resources, unconventional water sources such as mine water (the water drained from mines during the operation) or municipal wastewater are progressively being adopted in this sector. While not a panacea and not exempt from challenges, this could help reduce both the power plants’ impact on water resources and their exposure to water risks.

Thermal power contribution to water stress

China’s power sector is both contributing and exposed to water stress, as highlighted in various recent reports – including CWR’s ‘Toward A Water & Energy Secure China’ for an overview of the challenges regarding water & energy in China, or CWR-IRENA’s ‘Water Use in China’s Power Sector’ for the expected impact of China’s power sector on water and climate by 2030.

The power sector is China’s largest industrial water user; it’s responsible for 12.3% of freshwater withdrawal

In China, it is estimated that energy production is responsible for 12.3% of national freshwater withdrawal. Water use in thermal power plants represent the bulk of this at around 10%, being the largest user of water after irrigation and consequently the largest industrial water user. In these power plants, water is mainly used for cooling purposes. Part of the water withdrawn is returned to the local catchment at a warmer temperature; the remainder is “lost” mainly through evaporation and is referred to as water consumption. Nationally, this “water loss” accounts for a modest 2% of China’s water consumption. However, geographical mismatch exacerbates the impact of these water plants on local water resources.

Freshwater-reliant power plants mainly located in water stressed regions

In the map below, we show the distribution of thermal power generation relying on freshwater (i.e. excluding power generation relying on seawater). As can be seen, most of freshwater-reliant thermal power plants are located in extremely water stressed and arid regions, shown in dark red and grey colours. Power plants are therefore both contributing and exposed to water stress.

Yet not all power plants are equal in terms of water use. Dry cooling technology, also called air cooling, is often mentioned as a way to overcome the water & power conundrum. China has largely adopted this technology in Northern areas with air cooled power plants representing more than half of thermal power generation in Inner Mongolia, Shanxi, Shaanxi and Ningxia for instance.However, the associated water savings come at the cost of additional coal consumption and pollutant emissions. Moreover, despite its name, air-cooled power plants still use a non-negligible amount of water, mainly for pollution treatment purposes. A complementary approach, if not an alternative, consists of relying on “unconventional” sources of water.

Municipal wastewater & mine water as potential water sources

While thermal power plants located near the coast can rely on seawater, inland power plants usually rely on surface water bodies (e.g. rivers, lakes) and in rare cases on groundwater reserves (although prohibited for new power plants). Yet other options are available for these thermal power plants to reduce their use of precious water resources.

As highlighted in a recent report by the IEA Clean Coal Centre, unconventional water sources exist that can quench power plants’ thirst, including municipal wastewater, mine water and water from deep saline aquifers. Relying on such water sources can benefit the environment by reducing the amount of surface water withdrawn as well as the amount of wastewater discharged in surface water bodies.

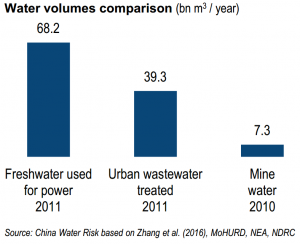

In order to get a sense of magnitude, the right-hand chart compares the amount of freshwater used by the power sector against the amount of wastewater treated in urban treatment plants as well as the amount of mine water drained. This does not account for industrial wastewater treated in companies’ or parks’ own treatment plants.

This first approximation shows that these unconventional sources can be an important substitute for surface water in thermal power plants. And China has indeed been promoting such water sources for years already.

Unconventional water sources: from encouraging to requiring their use

As just mentioned, policies already exist in China to promote the utilisation of unconventional water sources, both by requiring industries to use more of it (“demand pull”), and by asking other industries to provide more of it (“supply push”).

No new water use permits will be issued for thermal power plants that do not fully utilise the potential of reclaimed water

On the “demand” side, as early as 2004, NDRC encouraged new coal power plants to use treated wastewater in Northern China. In 2013, the Ministry of Water Resources forbid the use of groundwater in power bases while demanding that they give priority to mine water or reclaimed water. And last year, the ‘Water Pollution Prevention & Control Action Plan’ took a step further and declared that no new water use permits will be issued for thermal power plants that do not fully utilise the potential of reclaimed water.

China is also acting on the “supply” side, for instance through setting high mine water recycling targets. By 2020, 75% to 95% of mine water should be reused, depending on local water scarcity. Wastewater treatment plants are also progressively getting more ubiquitous in China – more on this here – and hence more treated wastewater is available for other purposes.

Use of unconventional sources still marginal, but growing fast in some regions

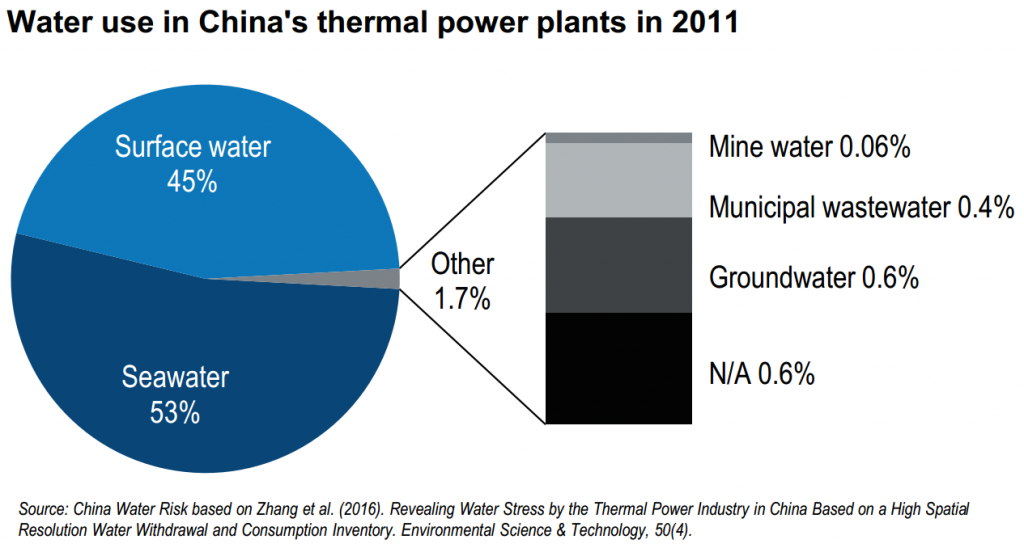

According to the latest data available, the adoption of unconventional water sources for thermal power plants was still marginal in China in 2011, as seen in the chart below.

Unconventional water sources (excl. seawater) represent less than 1% of water for power…

…seawater represents: > 50%

Given the historical development of coal power plants on China’s East coast, seawater represents more than half of the water used in thermal power generation. In turn, mine water and municipal wastewater represent less than 0.5% of water use nationally. As a comparison, around 5% of coal power plants in the US rely on municipal wastewater.

Common with national data, China’s national average hides much variation across provinces. According to the latest data available, Liaoning province relied on unconventional water sources for 34% of its freshwater use in power sector in 2011. In main coal provinces, this share lies between 0% and 17% whilst the figure varies between 1% and 21% when looking at Northern river basins – see chart below.

Reclaimed water accounts for ~58% of recently issued water use quotas for new coal power plants in the Yellow River Basin

However, as mentioned, the data dates back to 2011 and these shares could have been growing fast since then. According to another study, reclaimed water from wastewater treatment plants accounted for 58% of water withdrawal quotas issued for new coal power plants in the Yellow River Basin during 2009-2014. With the planned development of coal bases in inland and water stressed areas, these unconventional water sources should play a more important role in the short term; easier said than done though given the constraints facing such approaches.

Economic and technological challenges remain

Using reclaimed water for thermal power plants pose several challenges, both economic and technological. Transportation and treatment costs first come to mind, as these would increase the cost of water for power companies. One should note, however, that economic rationale has not always been the determining factor in power development decisions. For instance, China has extensively built air-cooled power plants despite their higher construction and operating costs. Water constraints may here again justify additional investments from the coal, power or water companies.

Moreover, in our last report we saw that water tariffs represented less than 1% of electricity production costs. For companies, the main challenge is thus not to have access to cheap water but rather to be allocated enough water use quotas.

Investing in unconventional water sources is therefore more of a risk-mitigation strategy than a cost-reduction one. Other challenges concern the water quality and its continuous availability. The IEA Clean Coal Centre report also mentions operational problems associated with the use of municipal wastewater, including corrosion and biofouling of pipes and cooling systems. Yet these constraints as well as other human health concerns can be overcome with adequate water treatment and management.

More benefits of unconventional water sources yet to be tapped

Using unconventional water sources won’t entirely alleviate power plants’ impact on water resources: one cubic meter of water evaporated is still one cubic meter of water evaporated, regardless of where it came from. There are however other benefits that could be expected from growing use of mine water and municipal wastewater.

Using mine water or municipal wastewater would for instance incentivise companies to properly treat it, not only for the sake of complying with regulations but also for their technical ability to operate. It could also help struggling treatment plants find much-needed additional revenue streams. Ultimately, diversifying water sources is a risk-mitigation strategy that could benefit both power companies and provinces that have to deal with tight water allocation quotas and water pollution targets.

This entry was posted on Wednesday, October 19th, 2016 at 5:49 am and is filed under Uncategorized. You can follow any responses to this entry through the RSS 2.0 feed. You can leave a response, or trackback from your own site.

Leave a Reply

You must be logged in to post a comment.

Educated at Yale University (Bachelor of Arts - History) and Harvard (Master in Public Policy - International Development), Monty Simus has held a lifelong interest in environmental and conservation issues, primarily as they relate to freshwater scarcity, renewable energy, and national park policy. Working from a water-scarce base in Las Vegas with his wife and son, he is the founder of Water Politics, an organization dedicated to the identification and analysis of geopolitical water issues arising from the world’s growing and vast water deficits, and is also a co-founder of SmartMarkets, an eco-preneurial venture that applies web 2.0 technology and online social networking innovations to motivate energy & water conservation. He previously worked for an independent power producer in Central Asia; co-authored an article appearing in the Summer 2010 issue of the Tulane Environmental Law Journal, titled: “The Water Ethic: The Inexorable Birth Of A Certain Alienable Right”; and authored an article appearing in the inaugural issue of Johns Hopkins University's Global Water Magazine in July 2010 titled: “H2Own: The Water Ethic and an Equitable Market for the Exchange of Individual Water Efficiency Credits.”